Fuels

Showing all 10 results

-

Hot

Automatic Cloud and Pour Point Analyzer

$7,000.00The Automatic Cloud and Pour Point Analyzer is a state of the art piece of equipment for measuring cloud point by optical detection and pour point with automatic tilt. The cloud point is an index of the lowest temperature of a petroleum product or a biodiesel fuel’s utility for certain applications. Wax crystals of sufficient quantity can plug filters used in some fuel systems. The pour point of a petroleum product is an index of the lowest temperature of its utility for certain applications. Flow characteristics, such as pour point, can be critical for the correct operation of lubricating oil systems, fuel systems, and petroleum blending and pipeline operations.

-

Hot

Automatic Density Meter

$5,000.00Density is a fundamental physical property that can be used in conjunction with other properties to characterize the quality of crude oils, light and heavy fractions of petroleum and petroleum products. The test method covers the determination of the density or relative density of crude oils, petroleum distillates and viscous oils that can be handled in a normal fashion as liquids at test temperatures between 15 and 35°C.

-

Hot

Automatic Heated Oil Test Centrifuge

$3,000.00Fully automatic bench top centrifuge designed expressly for petroleum testing applications. Features a 4-1/2” LCD touch screen control panel. This integrated touch screen can be used to turn the heat on and off, set the duration of the test, set the RCF/RPM values and choose the type of rotor assembly and corresponding glassware to be used during the test. The Servoed motor speed mechanism allows the user to simply set the desired speed and the instrument will attain that speed. This mechanism calculates RPM based on the given RCF and type of rotor selected. The large, clear, top opening lid provides for easy access to the rotor and tube holders and for cleaning of the unit. The lid has a 18-1/2” diameter viewing window allowing the operator to view inside the chamber for checking the status of the rotor and checking for possible spillage of the centrifuge tubes. Molded PTFE cushions provide for maximum protection and easy positioning of the tubes. The Centrifuge comes equipped with a safety lockout mechanism. Upon emergency shutdown, the door is locked and cannot be unlocked until the unit comes to a complete stop, the unit is turned back on, and the stop/unlock key is pressed on the touch screen display. Furthermore, the centrifuge cannot start while the door of the chamber is open and the latch is not engaged. The “Nitrogen Purge” feature allows for a slow release of nitrogen into the bowl of the centrifuge. This feature requires an external nitrogen gas source and can easily connect to an inlet port located at the back of the unit.

-

Hot

Automatic Pensky-Martens Closed Cup Flash Point Tester

$19,800.00The Automatic Pensky-Martens Closed Cup Flash Point Analyzer represents a perfect union of next-generation technology with traditional robust quality. The system software runs on an integrated processor PC running the latest Windows operating system. The 8.4” touch screen interface fully displays all operator parameters and results on a single screen. A three (3) position mechanical lift system for the cover and motor assembly is fully automated and software selectable: Open – Clean – Test for one touch positioning of the test cup. The instrument comes standard with two flash detector systems including a thermocouple and ionization ring detection. Over 65,000 results of data can be stored on the local hard drive. Integrated Dual Fan System directly cools the test cup and the environment around test cup. An unlimited number of user programs can be applied, including a quick test that safely tests from ambient, puts the flash point result into the EFP of the official run, and prompts user to refresh the sample, virtually assuring no fires ever occur. In addition, the instrument comes standard with an inert gas fire suppression system.

-

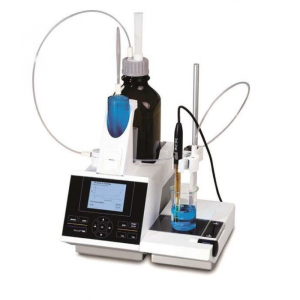

Automatic Volumetric Karl-Fischer Titrator

$7,000.00The actual curve and the measurement drift during titration process appear in the display and you can see the titration solvent consumption. Standard methods for different applications are programmed.

The measurement uses a potentiometric titration method in an anhydrous medium. The titration with titrant starts, once the sample is dosed into the reagent. The user has to enter the sample weight into the menu. The titration speed is precisely adjusted to the reaction rate by control algorithms. The titration is performed automatically until the endpoint indication of measurement. At the end of the measurement, results are shown in ppm water or several other units.

-

Combination Octane Rating Unit Engine

$23,000.00The K90901 Standard Model Combination Octane Rating Unit is the latest model of octane engines with many easy-to-use features including automatic functions and enhanced documentation capabilities, conforming to the latest ASTM D2699 (RON) and ASTM D2700 (MON) test methods.

Through the engine’s operating panel, the parameters are adjustable according to the ASTM D2699 and D2700 specifications. The professional and clear design of the operating area makes the octane rating operation convenient and the data is easy to read and record. The auto-setting function of the octane engine effectively simplifies operational procedures and improves the efficiency of octane testing. The operating panel is equipped with a protect system and push-button switches to avoid improper operation.

-

Copper Strip Corrosion from Lubricating Grease

$11,000.00Immersion circulating water bath immerses Copper Strip Corrosion Test jars at the required depth per ASTM specifications. Use for testing lubricating oils and lubricating greases. Fully insulated, double-wall stainless steel construction.

-

Digital Penetrometer

$8,000.00Microprocessor-based penetrometer loaded with advanced features to provide ease of operation and highly reproducible consistency measurements of petroleum products. Microprocessor control provides a full range of measurement and reporting options, and operation is simplified by four user-programmable presets that facilitate lowering the penetrator tip to the sample surface.

Automatically timed penetrations—The penetrometer defaults to the standard ASTM interval of 5.0 seconds, or the operator may conveniently program a different interval in the range between 0.1 and 9999.9 seconds (in 0.1 second increments). A curing or temperature stabilization period may also be programmed by the operator (to delay the release of the penetrator into the sample) and for added convenience all selected parameters are retained in memory and automatically repeated in subsequent tests until changed by the operator. Separate keypad controls for each parameter simplify operation. Penetration and delay intervals count down on a large, easy to read LCD on the head of the unit.

Convenient measurement and reporting options—Penetration measurements in the full range of 0 – 620 in 1⁄10mm scale are reported in either 1⁄10mm or 1⁄100mm increments at the operator’s option. For quality control testing, a penetration range can be entered into memory prior to testing. If a test result falls outside of the programmed range, an audible signal and visual error message alert the operator of a failed sample. Test results are displayed in digital format on a large LCD readout on the head of the penetrometer and can be communicated to a printer or computer via a built-in RS232 interface.

Simplified penetrator tip placement—Correct placement of the penetrator tip on the sample surface is essential for accurate penetration test results. The Koehler Digital Penetrometer has four operator programmable presets that lower the penetrator to the sample surface height at the touch of a button, greatly simplifying the process to ensure reproducibility. A fine adjustment button permits slight adjustments as needed. Full manual operation is also available with the use of coarse and fine push button controls and built-in magnifier and illuminator arms. When testing electrically conductive samples, a built-in circuit senses the sample surface for automatic placement. After testing, the penetrometer head returns to a raised position at the touch of a button to facilitate cleaning of the penetrator and changing of the sample.

More convenience features—The detachable machined base provides a large platform to accommodate a wide range of sample containers and constant temperature cylinders. It removes easily to permit the head assembly to be reversed (for use with a constant temperature bath) or mounted directly to a bath housing or other location. A built-in rechargeable battery pack permits field operation and provides back-up in the event of power interruption. Battery recharges automatically during operation of the penetrometer on standard AC electrical service.

-

Existent Gum Evaporation Bath

$13,000.00Electrically heated baths for determining existent gum in aircraft turbine fuels by steam-jet evaporation and in motor and aviation gasolines by air-jet evaporation. Fully insulated, aluminum block design assures safe, efficient high temperature operation. Equipped with air/steam pressure regulator with gauge and a digital flowmeter for adjusting air flow per ASTM specifications. Stainless steel jets deliver air or steam flow to the test wells through removable brass conical adapters. Microprocessor PID control provides quick temperature stabilization without overshoot and the bath is protected by an over-temperature control circuit that interrupts power should the bath temperature exceed a programmed cut-off point. Dual LED displays provide actual and setpoint temperature values in °C/°F format.

Model K33900 with Built-in Superheater – Six-unit bath with a built-in thermostatically controlled superheater which delivers dried steam to the bath inlet for steam-jet method testing of aircraft turbine fuels. Has digital indicating solid state bath temperature control with digital setpoint and display.

Model K33780 – Three-unit bath without built-in superheater. All controls are housed in the bath cabinet. For steam-jet method testing of aircraft turbine fuels. Meets output requirements of three-unit and six-unit evaporation baths. Electrically heated for clean, efficient operation and ease of installation. Meets applicable ASME, NEC standards; UL listed, CSA approved. Electrically heated boiler provides instantaneous and reserve steam capacity for steam-jet evaporation tests. Easy to install and operate; electrical heating eliminates the need for on-site fuel combustion. Requires only a water feed source and electrical hook-up. Ruggedly constructed, with long-life industrial grade incoloy heating element. Includes a full range of safety features: automatic water level control and low water cut-off; steam safety valve; high-limit pressure cut-out with manual reset; steam pressure gauge.

-

Oxidation Stability Apparatus, 8-Place and 12-Place Bath

$22,000.00Constant temperature bath with solid state temperature control, calibrated flowmeters and condenser water manifold for oxidation stability tests on fuels and lubricants. Individual flowmeters and control valves for each oxidation cell deliver air flow at the rate of 3L/h. Condenser water manifold has individual control valves for each cell. Temperature controller provides quick temperature stabilization without overshoot, and the bath is protected by a redundant overtemperature control circuit that interrupts power should bath temperature exceed a programmed cut-off point. Display provides actual setpoint temperature values in °C/°F format. Communications software (RS232, etc.), ramp-to-set and other enhanced features are available as extra cost options. Double-wall insulated baths are equipped with copper immersion heaters and a 1⁄20 hp circulation stirrer. Stainless steel bath interior has a builtin support rack and overflow/drain to immerse the test cells at the required depth. Order oxidation cell glassware and accessories separately.